USE SALT, ELECTRICITY & WATER! SAFE & EASY!

100% TOTALLY GREEN, ORGANIC, ALL NATURAL, ENVIRONMENTALLY FRIENDLY.

BENEFITS: Safe & Easy to Use | Sterilization Time is 1 to 5 Minutes | Self-Cleaning | Cost Effective | Full Automation is Available | Fixed Strength Solutions | Simple Installation & Maintenance! Plus...Environmentally & Ecologically Friendly with NO Moving or Replaceable Parts!

The Envirolyte Solutions with their potent bactericidal and extractive qualities offer a wide range of applications to the farming industry. At the same time Envirolyte solutions achieve a substantial decrease in toxic emissions and with low costs, allow large savings over more expensive conventional methods. These solutions are safe to handle and there is no need to store hazardous chemicals.

The environmental and ecological benefits, particularly in terms of chemical reduction, are one of the prime factors for the use of Envirolyte and ECO units. These units are used for water purification, waste water and water purification throughout all major industries with particular impact on the agricultural industry.

ENVIROLYTE UNITS FEATURE THE FOLLOWING.

A self-cleaning cycle has been programmed into all machines which ensure easy maintenance, maximum productivity and long lifetime without maintenance.

The Envirolyte units have been developed to automatically produce activated solutions of different types and strength and to act as a stand-alone unit or for use in a continuous process in more complex systems. Design facility for customized units is available.

The unique design of the central cell ensures that the electrolyte used to produce activated solutions has maximum contact with the electrodes and therefore ensures the most effective use of energy and minimum waste of raw materials

The control system is simple and easy to operate. It can be altered to suit differing applications and conditions.

Stabilization of working current is introduced to ensure a stable quality of the generated solutions. Brine feed ventures and pinch valves are introduced to ensure accurate dosage under all conditions at any time.

The enclosure is made of non-corrosive materials. Tubes and connectors are of EPDM/PVDF plastics and are highly resistant against aggressive solutions.

All input and output connectors are located either at the rear or at one side of the unit to enable easy installation. There is a simply on/off switch with power indicator that starts and stops the unit manually and level-switches enable to start and stop the unit automatically.

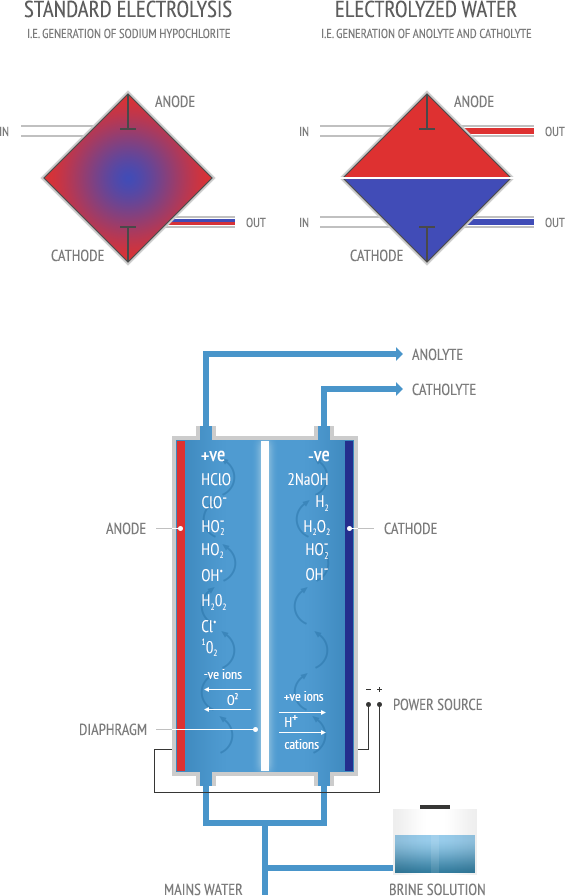

The Envirolyte units electrolyze salt (brine solution) and water using polymer or ceramic membrane to separate the positive and negative ions. As a result of the chemical reactions two types of activated solutions are produced: Anolyte-strong and fast-acting disinfectant which kills all known bacteria and viruses within minutes and Catholyte - an alkaline solution which removes heavy metals from water through precipitation or serves as an excellent washing liquid.

Electrochemistry is the part of science which deals with the interrelationship of electrical currents, or voltages, and chemical reactions, and with the mutual conversion of chemical and electrical energy. Electrolyzed Water (EW) Technology is based on a new, previously unknown law of anomalous changes of reaction and catalytic abilities of aqueous solutions subjected to electrochemical unipolar (either anodic or cathode) treatment. EW is necessarily associated with alteration of its chemical composition, acidity and (or) alkalinity within a wide range.

That is why EW application makes it possible:

- to exclude from routine technological processes the regulation of solution properties with costly reagents;

- to improve quality of the treated substances;

- to reduce the number and duration of technological operations;

- to decrease their labour-consuming nature;

- to facilitate and simplify processes of water and sewage purification.

Unlike well-known electrochemical reactions, in the processes of electrochemical activation initial substances are diluted aqua-saline (brine) solution and mains water. The eventual EW products are not concentrated chemical substances, but activated (Anolyte and Catholyte) solutions: low mineralised liquids in a metastable state, manifesting increased chemical activity. Synthesis of electrochemically activated solutions is only possible when unipolar electrochemical exposure is combined with treatment of as many as possible micro volumes of liquid in high voltage electric field of a double electric layer near the electrode’s surface.

The above stated conditions of producing activated solutions can be realized only in special diaphragmatic cells (round or square) which are the key elements of every Envirolyte or ECO unit.

The EW solutions produced by Envirolyte units (Anolyte and Catholyte) are channeled through canals and chambers and separated by the membranes. This unique patented process allows for more even distribution of electrolyte (brine solution) within the volumes of the chambers and reduces the risk of the formation of stagnant zones when flow rates of electrolyte are high. The construction of the diaphragmatic cells also allows highly effective evacuation of products of electrochemical and chemical reactions from the chambers.

UNIQUE DESIGN

A UNIQUE DESIGN FOR A UNIQUE PROCESS

At the core of the process are the patented diaphragmatic cells that have been designed using innovative and unique technology to effectively deliver electrochemically activated solutions (Anolyte and Catholyte) using a 1-4% water solution of NaCl as initial material.

Unlike other electrolytic cells, a diaphragm separates the Anolyte and Catholyte solutions that are generated respectively at the anode and cathode chambers of the cell. Thus preventing the two streams mixing and inter-reacting to form a simple sodium hypochlorite solution, as it is the case with other electrolytic cells that are commercially available at this time.

The Envirolyte cells are manufactured with variable Anolyte output capacity ranging from 20L to 1200L per hour of Anolyte out one cell. Combination of cells allows to main fracture Envirolyte units with output capacity up to 6000LPH.

UNIQUE AND INNOVATIVE

- It has been established by the National Industrial Fuel Efficiency Service Ltd. (NIFES), Scotland, UK through patent search that design of the Envirolyte diaphragmatic cells is unique and innovative.

EASY HANDLING

- The Envirolyte diaphragmatic cell is a round-shaped electrolyser, constructed of titanium and rare metals. The electrodes are separated by a polymer or ceramic diaphragm. Even under severe conditions hardly any element of the cell can be broken.

SMALL SIZE – HIGH CAPACITY

- With portable size of all Envirolyte cells they have production capacity varying from 20l up to 1200l of anolyte per hour. So with only one unit up to 20 – 1200 m3/h of water can be effectively disinfected or up to 1200 l/h of Anolyte directly dispensed.

VALUABLE BY-PRODUCT

- The production of Catolyte (if needed) by the diaphragmatic cells is a valuable addition to the synthesis of the activated solutions that can be used for washing or whenever it is necessary to increase pH of the treated water.

ENVIROLYTE UNITS

- Universal diaphragmatic cell for treatment of diluted and concentrated aqueous solutions, the heart of any Envirolyte unit.

DIAPHRAGMATIC CELL PERFORMANCE

In addition to the principal electro-chemical reaction that takes place at the electrodes, the high intensity of the electrical field at the electrode surface imparts a degree of electro-meta-stability to the water and its dissolved salts, increasing its ORP in the order of -800mv and + 1200mv respectively in the two streams .

.

This meta-stable condition has been found to remain for periods up to 72 hours after treatment and even more, retaining an inherently higher chemical reactivity and activity for this period of time and even longer (when activated solutions are properly stored they remain sporicidal and biocide for up to 6 months and still biocide for up to 12 months). The increased ORP enhances the solubility, dispersive and reactive properties of the water and its dissolved salts by a marked degree and is a significant indicator of biocide potential.

Properties of these solutions depend on electric characteristics of power supply and chemical composition of the treated solutions. The pH level of the solutions synthesised is controlled in the range pH 2.0-13.0, but is adjustable and can be set-up for specific parameters

Tags: Envirolyte Electrolyzed Water